If you walked into the kitchen of a Michelin-star restaurant and saw a chef washing dishes by simply soaking them in a sink of soapy water—without ever using a sponge or a brush—you would be horrified. You would know, instinctively, that the plates weren’t clean.

Yet, this is exactly how 90% of UK pubs clean their beer lines.

They fill the lines with chemical fluid. They leave it to soak. They rinse it out. They assume the job is done because the fluid changed colour.

They are wrong.

In the world of “Unreasonable Hospitality,” serving the perfect pint isn’t just about what you do; it’s about understanding the physics of what you are removing. If you are only using liquid line cleaner, you are doing only half the job.

To reach the standard of a “Category of One” operator, you need to introduce friction. You need The Torpedo Method.

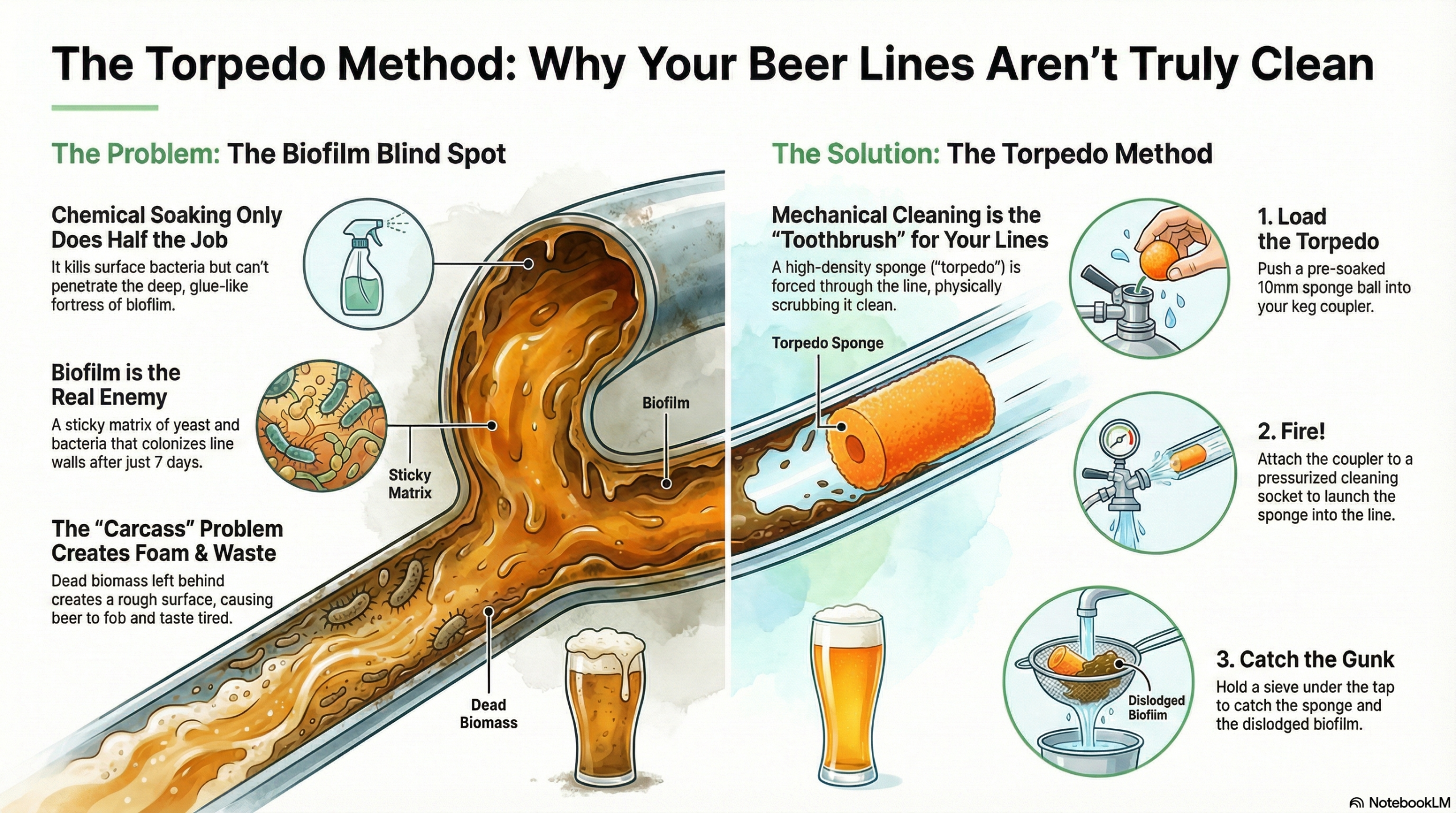

The Science: The Problem is “Biofilm,” Not Bacteria

To understand why your current cleaning regime is failing, you have to look at the enemy on a microscopic level.

Most landlords think they are fighting loose bacteria floating in the beer. If that were true, chemical fluid would work perfectly. But after just 7 days, yeast and bacteria don’t just float; they colonize. They attach themselves to the walls of your python lines and build a fortress called Biofilm.

Biofilm is a sticky, glue-like matrix (technically called Extracellular Polymeric Substance). It acts like a shield.

- The Chemical Failure: Standard purple line cleaner is excellent at killing the surface bacteria. But often, it cannot penetrate the deep layers of the biofilm matrix.

- The “Carcass” Problem: Even if your strong caustic cleaner kills the bacteria, it often leaves the dead body (the biomass) attached to the pipe wall.

This dead biomass is rough. It creates friction in the line. When carbonated beer hits this rough surface, it “nucleates”—breaking out of solution and turning into foam (fob).

The Result: You waste 3 pints of foam for every barrel, and your beer tastes “tired” because it is passing over a graveyard of dead yeast.

The Solution: Mechanical Cleaning (The “Torpedo”)

If chemicals are the “mouthwash,” mechanical cleaning is the “toothbrush.”

Mechanical cleaning involves forcing a physical object—a high-density sponge ball—through the line under pressure. As the sponge travels, it compresses against the pipe walls, physically scrubbing away the biofilm that the chemicals couldn’t dissolve.

We call this The Torpedo Method.

It is the secret weapon of the best cellar managers in the UK. It doesn’t just sanitise the line; it polishes it.

The Torpedo Method

Why chemical soaking is only 50% of the job. Stop serving beer from a “graveyard of dead yeast.”

If you walked into the kitchen of a Michelin-star restaurant and saw a chef washing dishes by simply soaking them in a sink of soapy water—without ever using a sponge or a brush—you would be horrified. You would know, instinctively, that the plates weren’t clean.

Yet, this is exactly how 90% of UK pubs clean their beer lines.

They fill the lines with chemical fluid. They leave it to soak. They rinse it out. They assume the job is done because the fluid changed colour.

They are wrong.

The Physics: Chemical vs. Mechanical

Scenario A: Chemical Soak

Chemicals kill bacteria but leave the “carcass” (biomass) attached to the wall. This roughness causes nucleation (fobbing).

Scenario B: The Torpedo

The “Fob Cost” Calculator

Biofilm creates friction. Friction creates foam. Calculate the annual cost of “good enough” cleaning.

Avg per line (soak method)

Annual Revenue Lost to “The Carcass”:

Assumes weekly line cleaning over 52 weeks.

The Gear: Retrofit Your Cellar for Under £50

You cannot execute the Torpedo Method with a standard gravity-fed cleaning bucket. You need a closed-loop pressure system.

-

1

The “Launch Chamber” (Cleaning Socket) Mounts to the wall. Allows you to load the sponge before engaging pressure. Don’t use a screwdriver to jam it in. Buy Launch Chamber →

-

2

The “Torpedoes” (10mm Sponge Balls) Crucial: Buy 10mm balls for 3/8″ lines. 9mm balls will float; 10mm balls will compress and scrub. Get Pro-Grade 10mm Balls →

The Protocol

Troubleshooting: “It’s Stuck!”

Don’t panic. 99% of “stuck” sponges are just sitting in the tap body. Unscrew the sparkler nozzle—you will usually see the orange sponge smiling at you.

The Gear: What You Need to Retrofit Your Cellar

You cannot execute the Torpedo Method with a standard gravity-fed cleaning bucket. You need a closed-loop pressure system. Here is the specific kit list you need to upgrade your cellar for under £50.

1. The “Launch Chamber” (Cleaning Socket)

Most landlords fail at mechanical cleaning because they try to force a sponge into the line with a screwdriver. This damages the coupler and creates leaks.

You need a Cleaning Socket (also known as a Ring Main Adapter). This device mounts to your cellar wall. It allows you to “load” the sponge into the keg coupler before you engage the water pressure. Without this adapter, you cannot generate the seal needed to fire the sponge.

- The Expert Choice: Ensure you buy the correct shape for your couplers (Sankey vs. Grundy).

- Buy the Cleaning Socket (Launch Chamber) Here

2. The “Torpedoes” (10mm Sponge Balls)

Size matters. The standard UK beer line (the drop from the python to the tap) is usually 3/8″ (9.5mm).

- The Mistake: Many people buy 9mm balls. These are too loose. They float through the line without scrubbing.

- The Fix: You need 10mm Sponge Balls. They are slightly larger than the pipe, meaning they have to compress to fit through. This compression creates the scouring action you need.

- Get the Pro-Grade 10mm Sponge Balls Here

Step-by-Step: How to Execute “The Torpedo”

This procedure is high-pressure. Follow these steps exactly to avoid a beer shower.

Step 1: The Pre-Soak

Never run a dry sponge through a dry line. It will squeak, snag, and potentially get stuck.

- Drop your 10mm Sponge Balls into a cup of water or diluted line cleaner for 2 minutes before starting.

Step 2: Load the Chamber

- Disconnect your keg coupler from the beer keg.

- Take one wet sponge ball.

- Push it manually up into the gas inlet (or the beer entry port) of the keg coupler. You only need to push it in just past the rubber washer.

- SNAP the coupler onto your wall-mounted Cleaning Socket.

- Why this works: The socket engages the probe, opening the valve. The sponge is now sitting in the “barrel” of the gun, waiting for the water pressure.

Step 3: Fire!

- Go to your cleaning pump or pressurized cleaning bottle.

- Turn on the flow (water or weak cleaning fluid).

- The pressure builds up behind the sponge. Whoosh. It is launched out of the coupler and into the beer line.

Step 4: The Catch (Crucial Safety Step)

Go to the bar. Do not just open the tap into a bucket. The sponge travels at high speed. If it shoots out of the tap, it can bounce into a drain, or worse, into a customer’s glass later if you lose it.

- The Rule: Hold a sieve or a colander under the tap spout.

- Open the tap.

- You will see a spurt of water, followed by the sponge ball, followed immediately by a plug of black/brown gunk.

That gunk is what you are paying for. That is the biofilm that your chemical cleaner left behind last week.

Troubleshooting: “What if it gets stuck?”

This is the number one fear of landlords, but it is easily managed. If the flow stops and the sponge doesn’t appear:

- Don’t Panic. It is usually stuck at a “restriction” point—likely the sparkler nozzle or a tight bend in the python.

- Reverse the Pressure: If you have a gas pump, simply disconnect the coupler and the line pressure will often push it back.

- Check the Tap: 99% of “stuck” sponges are actually just sitting in the tap body. Unscrew the nozzle/sparkler. You will likely see the orange sponge smiling at you.

- Prevention: Always cut a tiny “X” into the sponge ball with scissors before loading it. This makes it more flexible around 90-degree bends.

The “Expert Operator” Mindset

Why go to this effort? Why spend £20 on Sponge Balls and a Socket when soaking is “good enough”?

Because “good enough” is the enemy of profit.

A line free of biofilm pours faster. It fobs less. It allows you to serve a pint with a perfect head that lasts all the way to the bottom of the glass. It stops customers from leaving half a pint because it tasted “a bit soapy.”

Cleaning lines isn’t a chore; it is profit protection.

Speaking of Profit Protection: If you are serious about reducing waste in your cellar, you should be equally obsessive about waste in your kitchen. We have developed a tool that uses local data to predict exactly how many Sunday Roasts you will sell, so you stop throwing away profit on Monday morning. Try the Sunday Roast Forecaster Here